PLET Support Tower Heerema

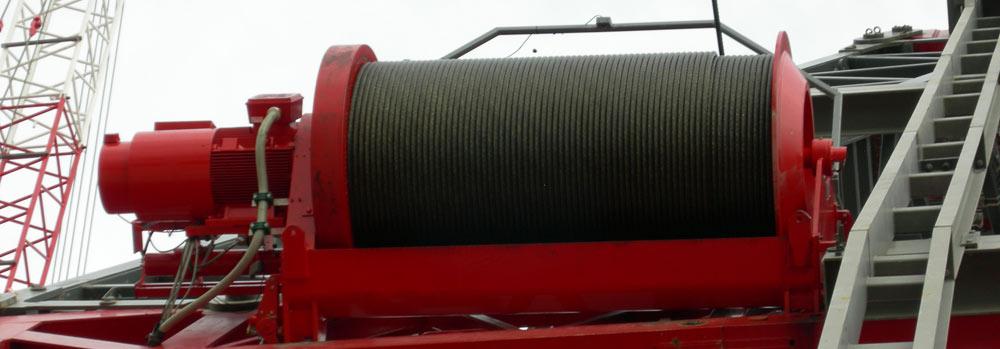

The PLET support tower is designed for Heerema Marine Contractors. It’s purpose is to lift existing pipeline-ends from great depth (2200m) to the surface, install a new PLET (Pipe Line End Termination) and lower the end back to the seabed. For lifting and lowering of the pipe- end a 600T traction winch is used. Above water level the load is transferred from the traction winch to one of the Thialf cranes. The crane then places the pipe-end in the HOT (Hang Off Table) where the pipe end can be cut, cleaned and prepared for welding on the PLET. Then a new PLET is installed in the tower and welded to the pipe-end. After coating the welded parts, the pipe including PLET is lowered back to the seabed.

Size approx 50m high, Lifting capacity 600T, location: on board of Thialf, Owner Heerema Marine Contractors.

Asisto part in this project:

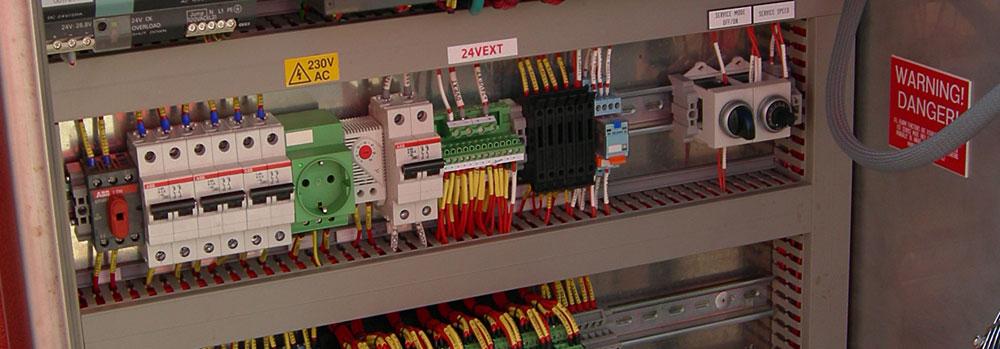

- PLC cabinet, based on Siemens S7-300

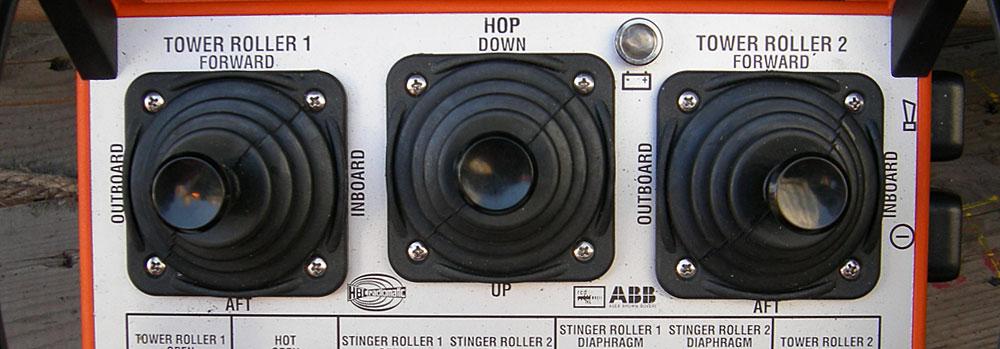

- Control desk and control screen

- 46” Status screen in air conditioned cabinet

- 15 Siemens remote I/O control cabinets, stainless steel including sun protection. All Siemens PLC components are Siplus types, suitable for 60˚C.

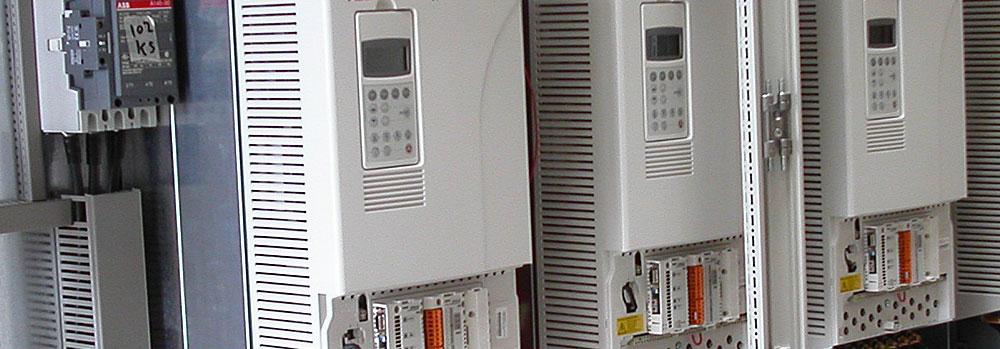

- Powerpack 2x65kW control cabinet, stainless steel

- 7-Function Manipulator control cabinet, stainless steel

- 4000A breaker cabinet for 440V/230V/110V distribution

- 10kVA UPS and breaker cabinet

- Radio control for tower

- Angle, proximity and length transmitters

- Software for PLC’s and screens. PLC software developed using S7-professional, SCL and LAD. Screen software developed using Citect Scada.

- All cable trays, cables, supports and junction boxes on the tower and in the work shop

- All floodlights on the tower

- All lights, outlets and breaker boxes in the work station

- Lightning protection of the tower

- Install and commissioning of all the above in the Gulf of Mexico, USA